Types of Corrugated

Sustainable packaging solutions

Total Packaging Solutions offers one of the most comprehensive portfolios of corrugated packaging solutions in North America. Our eco-friendly, corrugated fiberboard, are used in a wide variety of packaging applications for some of the worlds largest and most respected brands.

What is corrugated fiberboard?

Corrugated fiberboard, or cardboard (as it’s sometimes referred) is a paper-based material that consists of a fluted corrugated sheet and one or two flat linerboards. The smooth, flat paper that sandwiches the interior fluting is the linerboard. The fluted paper (or medium as it is sometimes referred) is joined to the flat linerboard with an adhesive to form the corrugated fiberboard.

Two design factors impact the weight, strength, qualities and characteristics of corrugated when it comes to automotive packaging applications: fluting and wall construction.

Wall construction is the most straightforward design factor. Corrugated cardboard walls are manufactured in single, double, and even triple-wall thicknesses. The more layers in the cardboard wall, the greater the strength. However, if an automotive customer is having stacking or crushing issues, they should not immediately move to double wall corrugated. There are design implementations, handling concerns, and raw material concerns that should be looked at first.

Corrugated flutes

The inventors of corrugated board applied similar science to paper as ancient architects did to buildings. When trying to uphold heavy loads, strength is unsurpassed when using an arch. Generally the larger flute profiles give greater vertical strength and cushioning. The smaller flutes help enhance graphic capabilities while providing greater structural integrity. By experimenting with flute profiles, designers can vary compression strength, cushioning strength and thickness.

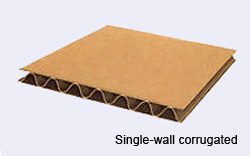

• Single-wall corrugated sheet

Single-wall corrugated boxes have a wide range of material strength, which is measured in terms of the Edge Crush Test (ECT). The ECT test identifies the strength of the corrugated cardboard per square inch when crushed. The ability of the assembled box to withstand weight before bursting is measured with the Mullen Bursting Test. Single-wall corrugated boxes start at 23 ECT and range up to 55 ECT. Most single-wall corrugated boxes come in 200# to 275# bursting test strength. Very lightweight single-wall boxes will have a maximum box weight of 20 lbs., a bursting test weight of 125 lbs., and an ECT of 23 lbs. per square inch.

• Double-wall corrugated packaging

Double-wall cardboard is automatically stronger and more resistant to crushing than single-wall cardboard. Heavier and less flexible than single-wall corrugated material, double-wall corrugated cardboard is designed to accommodate heavier contents for shipping and storage. Double-wall corrugated cardboard strengths range from 42 ECT to 82 ECT. Double-wall corrugated boxes have minimum bursting test weights starting at 200 lbs. and going up to 600 lbs.

• Triple-wall corrugated packaging

Triple-wall corrugated boxes contain three corrugated mediums and four linerboard facings. This 7-ply construction is used where large container sizes are involved, such as pallet packs. Triple-wall corrugated boxes can hold significantly more weight, ranging from 240 to 300 lbs., with 67 to 112 ECT. Triple-wall corrugated boxes are the heaviest type, and can hold significantly more weight, ranging from 240 to 300 lbs., with 67 to 112 ECT.

What is fluting?

Fluting is the element of corrugated cardboard that contributes to material strength for stacking, resistance to crushing, or suitability for other uses, such as graphic reproduction. The types of fluting vary depending upon how many flutes are included per foot, and how thick the fluting is.

There are five standard types of fluting:

A-flute:

A-flute is the first type of corrugated cardboard invented. With 36-flutes/linear foot it is often used for wrap, cushioning or stacking.

B-flute:

Has 49-flutes/linear foot, and appears thinner than other types, but is strong, and is most often used for die-cut boxes, canned goods and displays.

C-flute:

With 41-flutes/linear foot, C-flute is thinner than A-flute, and thicker than B-flute, with flexibility in use. C-flute is the most common type of corrugated container material used in the automotive industry, and is the typical corrugated cardboard found in regular slotted shipping cartons (RSCs).

E-flute:

Has 95-flutes/linear foot, and is one-fourth of the thickness of C-flute, E-flute is found in cosmetics boxes, glass and ceramic containers -- and pizza boxes. This fluting is commonly used with glued-in partitions for automotive customers.

F-flute:

The newest type of corrugated cardboard; F-flute has 128 flutes/foot, is only half the thickness of E-flute, and is currently expanding in use because it can reduce the total amount of paper fiber in packaging for a more sustainable solution. Highly publicized adoptions of F-flute include McDonalds restaurant sandwich packaging, reducing total weight and paper use.